You probably know my robot. I’ve been inventing autonomous machines for over 30 years and one of them, Roomba from iRobot, is quite popular. During my career, I’ve learned a lot about what makes robots valuable, and formed some strong opinions about what we can expect from them in the future. I can also tell you why, contrary to popular apocalyptic Hollywood images, robots won’t be taking over the world anytime soon. But that’s getting ahead of myself. Let me back up.

My love affair with robots began in the early 1980s when I joined the research staff at MIT’s Artificial Intelligence Lab. Physics was my college major but after a short time at the lab the potential of the developing technology seduced me. I became a roboticist.

Such an exhilarating place to work! A host of brilliant people were researching deep problems and fascinating algorithms. Amazingly clever mechanisms were being developed, and it was all converging in clever and capable mobile robots. The future seemed obvious. So, I made a bold prediction and told all my friends, “In three to five years, robots will be everywhere doing all sorts of jobs.”

But I was wrong.

Again and again in those early years, news stories teased: “Big Company X has demonstrated a prototype of Consumer Robot Y. X says Y will be available for sale next year.” But somehow next year didn’t arrive. Through the 1980s and 1990s, robots never managed to find their way out of the laboratory. This was distressing to a committed robot enthusiast. Why hadn’t all the journal papers, clever prototypes, and breathless news stories culminated in a robot I could buy in a store?

Let me answer with the story of the first consumer robot that did achieve marketplace stardom.

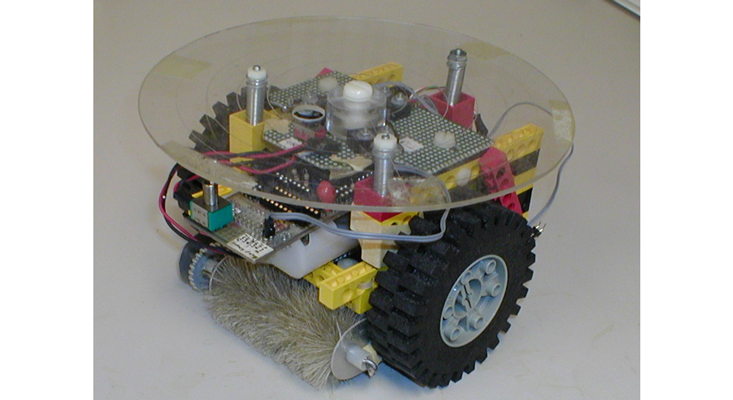

In the summer of 1999, while working at iRobot, a colleague, Paul Sandin, and I wrote a proposal titled “DustPuppy, A Near-Term, Breakthrough Product with High Earnings Potential.” We described an inexpensive little robot, DustPuppy, that would clean consumers’ floors by itself. Management liked the idea and gave us $10,000 and two weeks to build a prototype.

Using a cylindrical brush, switches, sensors, motors, and a commonplace microprocessor, we assembled our vision. At the end of an intense fortnight we had it—a crude version of a robot that conveyed a cleaning mechanism around the floor and—mostly—didn’t get stuck. Management saw the same promise in DustPuppy as Paul and me.

We called our robot DustPuppy for a reason. This was to be the world’s first significant consumer robot and the team’s first attempt at a consumer product. The risk was that customers might expect too much and that we might deliver too little. We were sure that—like a puppy—our robot would try very hard to please but that also—like a puppy—it might sometimes mess up. Calling it DustPuppy was our way of setting expectations and hoping for patience if our robot wasn’t perfect out of the gate. Alas, iRobot employed a firm to find a more commercial name. Many consumer tests later, DustPuppy became Roomba. The thinking was the robot’s random motion makes it appear to be dancing around the room—doing the Rumba.

Paul and I knew building a robotic floor cleaner entails fierce challenges not apparent to the uninitiated. Familiar solutions that work well for people can prove problematic when applied to a robot.

Your manual vacuum likely draws 1,400 watts or 1.9 horsepower from the wall socket. In a Roomba-sized robot, that sort of mechanism would exhaust the battery in about a minute. Make the robot bigger, to accommodate a larger battery, and the robot won’t fit under the furniture. Also, batteries are expensive—the cost of a big one might scuttle sales. We needed innovation.

Melville Bissell, who patented the carpet sweeper in 1876, helped us out. We borrowed from his invention to solve Roomba’s energy problem. A carpet sweeper picks up dirt very efficiently. Although you supply all the power, you won’t work up a sweat pushing one around. (If you supplied the entire 1.9 horsepower a conventional vacuum needs, you’d do a lot of sweating!)

When designers festoon their robots with anthropomorphic features, they are making a promise no robot can keep.

We realized that our energy-efficient carpet sweeper would not clean as quickly or as deeply as a powerful vacuum. But we thought, if the robot spends enough time doing its job, it can clean the surface dirt just as well. And if the robot runs every day, the surface dirt won’t work into the carpet. Roomba matches a human-operated vacuum by doing the task in a different way.

Any robot vacuum must do two things: 1) not get stuck, and 2) visit every part of the floor. The first imperative we satisfied in part by making Roomba round with its drive wheels on the diameter. The huge advantage of this shape is that Roomba can always spin in place to escape from an object. No other shape enables such a simple, reliable strategy. The second imperative, visiting everywhere, requires a less obvious plan.

You move systematically while cleaning, only revisiting a spot if that spot is especially dirty. Conventional wisdom says our robot should do the same—drive in a boustrophedon pattern. (This cool word means writing lines in alternate directions, left to right, right to left, like an ox turns in plowing.) How to accomplish this? We received advice like, “Just program the robot to remember where it’s been and not go there again.”

Such statements reveal a touching faith that software unaided can solve any technical problem. But try this exercise (in a safe place, please!). While standing at a marked starting point, pick another point, say, six feet to your left. Now keep your eyes closed while you walk in a big circle around the central point. How close did you come to returning to your starting point? Just like you, a robot can’t position itself in the world without appropriate sensors. Better solutions are available today, but circa 2000 a position-sensing system would have added over $1,000 to Roomba’s cost. So, boustrophedon paths weren’t an option. We had to make Roomba do its job without knowing where it was.

I design robots using a control scheme called behavior-based programming. This approach is robot-appropriate because it’s fast, responsive, and runs on low-cost computer hardware. A behavior-based program structures a robot’s control scheme as a set of simple, understandable behaviors.

Remember that Roomba’s imperative is to apply its cleaning mechanism to all parts of the floor and not get stuck. The program that accomplishes this needs a minimum of two behaviors. Call them Cruise and Escape. Cruise is single-minded. It ignores all sensor inputs and constantly outputs a signal telling the robot’s motors to drive forward.

Escape watches the robot’s front bumper. Whenever the robot collides with something, one or both of the switches attached to the bumper activate. If the left switch closes, Escape knows there’s been a collision on the left, so it tells the motors to spin the robot to the right. A collision on the right means spin left. If both switches close at once, an arbitrary decision is made. When neither switch is closed Escape sends no signal to the motors.

Occasionally Cruise and Escape try to send commands to the motors at the same time. When this happens, a bit of code called an arbiter decides which behavior succeeds—the highest priority behavior outputting a command wins. In our example, Escape is assigned the higher priority.

Watching the robot, we see a complex behavior emerge from these simple rules. The robot moves across the floor until it bumps into something. Then it stops moving forward and turns in place until the path is clear. It then resumes forward motion. Given time, this random motion lets the robot cover, and clean, the entire floor.

Did you guess so little was going on in the first Roomba’s brain? When observers tell me what Roomba is thinking they invariably imagine great complexity—imbuing the robot with intentions and intricate plans that are neither present nor necessary. Every robot I build is as simple and simple-minded as I can make it. Anything superfluous, even intelligence, works against marketplace success.

The full cleaning task contains some extra subtleties. These require more than just two behaviors for efficient operation. But the principle holds, the robot includes only the minimum components and code required for the task.

A few months from product launch, we demonstrated one of our prototypes to a focus group. The setup was classical: A facilitator presented Roomba to a cross section of potential customers while the engineers watched from a darkened room behind a one-way mirror.

The session was going well, people seemed to like the robot and it picked up test dirt effectively. Then the facilitator mentioned that Roomba used a carpet sweeper mechanism and did not include a vacuum.

The mood changed. Our test group revised the price they’d be willing to pay for Roomba, cutting in half their estimate from only minutes earlier. We designers were perplexed. We solved our energy problem by eschewing a vacuum in favor of a carpet sweeper—and it worked! Why wasn’t that enough for the focus group?

Did you guess so little was going on in Roomba’s brain? Every robot I build is as simple-minded as I can make it.

Decades of advertising have trained consumers that a vacuum drawing lots of amps means effective cleaning. We wanted customers to judge our new technology using a more appropriate metric. But there was no realistic way to accomplish that. Instead, our project manager declared, “Roomba must have a vacuum, even if it does nothing.”

No one on the team wanted a gratuitous component—even if it solved our marketing problem. We figured we could afford three watts to run a vacuum motor. But a typical vacuum burns 1,400 watts. What could we do with just three?

Using the guts of an old heat gun, some cardboard, and packing tape, I found a way. It turned out that if I made a very narrow inlet, I could achieve the same air-flow velocity as a regular vacuum but, because the volume was miniscule, it used only a tiny bit of power. We had a vacuum that actually contributed to cleaning.

There’s a moment in the manufacturing process called “commit to tooling” when the design must freeze so molds for the plastic can be cut. Fumble that deadline and you may miss your launch date, wreaking havoc on your sales.

About two weeks before “commit,” our project manager said, “Let’s test the latest prototype.” We put some surrogate dirt on the floor and let Roomba run over it. The dirt remained undisturbed.

Panic ensued. Earlier prototypes had seemed to work, and we thought we understood the cleaning mechanism. But maybe not. I returned to the lab and tried to identify the problem. This involved spreading crushed Cheerios on a glass tabletop and looking up from underneath as our cleaning mechanism operated.

Our concept of Mr. Bissell’s carpet sweeper went like this: As the brush turns against the floor, bristle tips pick up dirt particles. The brush rotates inside a conforming shroud carrying the dirt to the back where a toothed structure combs it from the brush. The dirt then falls into the collection bin.

That sedate description couldn’t have been more wrong. In fact, as the brush turns against the floor, a flicking action launches dirt particles into a frenetic, chaotic cloud. Some particles bounce back onto the floor, some bounce deep into the brush, some find the collection bin. The solution was to extend the shroud around the brush a little farther on the back side—that redirected the dirt that bounced out such that the brush had a second chance to pick it up. Roomba cleaned again and we could begin cutting molds with a day or two to spare.

Roomba launched in September 2002. Its success rapidly eclipsed the dreams of all involved.

Did Roomba’s nascent reign end the long robot drought? Was my hordes-of-robots-in-service-to-humanity dream about to come true?

In the years since iRobot released Roomba, many other robot companies have cast their die. Here are a few: Anki, Aria Insights, Blue Workforce, Hease Robotics, Jibo, Keecker, Kuri, Laundroid, Reach Robotics, Rethink Robotics, and Unbounded Robotics. Besides robots and millions of dollars of venture capitalist investment, what do all of these companies have in common? None are in business today.

The commercial failure of robots and robot companies is not a new phenomenon. Before Roomba, the pace was slower, but the failure rate no less disappointing. This dismal situation set me looking for ways around the fatal missteps roboticists seemed determined to make. I settled on three principles that we followed while developing Roomba.

1. Perform a Valuable Task

When a robot does a specific job, say, mowing your lawn or cleaning your grill, its value is clear and long-lasting. But over the years, I’ve seen many cool, cute, engaging robots that promised great, albeit vague, value while performing no discernable task. Often the most embarrassing question I could ask the designer of such a robot was, “What does your robot do?” In this case the blurted answer, “Everything!” is synonymous with “Nothing.” The first principle for a successful robot is: Do something people want done. When a robot’s only attribute is cuteness, value evaporates as novelty fades.

2. Do the Task Today

Many robots emerge from research labs. In the lab, researchers aspire to be first to achieve some impressive result; cost and reliability matter little. But cost and reliability are paramount for real-world products. Bleeding edge technologies are rarely inexpensive, reliable, or timely. Second principle: Use established technology. A research project on the critical path to robot completion can delay delivery indefinitely.

3. Do the Task for Less

People have jobs they want done and states they want achieved—a clean floor, a mowed lawn, fresh folded clothes in the dresser. The result matters, the method doesn’t. If a robot cannot provide the lowest cost, least arduous solution, customers won’t buy it. Third principle: A robotic solution must be cost-competitive with existing solutions. People will not pay more to have a robot do the job.

A few robots have succeeded impressively: Roomba, Kiva Systems (warehouse robots), and Husqvarna’s Automower (lawn mower). But I started this article with the question, why aren’t successful robots everywhere? Maybe the answer is becoming clearer.

Robot success is opportunistic. Not every application has a viable robotic solution. The state of the art means only select applications offer: a large market; existing technology that supports autonomy; a robotic approach that outcompetes other solutions.

There’s one more subtle aspect. Robots and people may accomplish the same task in completely different ways. This makes deciding which tasks are robot-appropriate both difficult and, from my perspective, great fun. Every potential task must be reimagined from the ground up.

My latest robot, Tertill, prevents weeds from growing in home gardens. A human gardener pulls weeds up by the roots. Why? Because this optimizes the gardeners time. Leaving roots behind isn’t a moral failure, it just means weeds will rapidly re-sprout forcing the gardener to spend more time weeding.

Tertill does not pull weeds but attacks them in two other ways. It cuts the tops off weeds and it uses the scrubbing action of the wheels to kill weeds as they sprout from seeds. These tactics work because the robot, unlike the gardener, lives in the garden. Tertill returns every day to prevent rooted weeds from photosynthesizing so roots eventually die; weed seeds that are constantly disturbed don’t sprout.

Had Tertill copied the human solution, the required root extraction mechanism and visual identification system would have increased development time, added cost, and reduced reliability. Without reimagining the task, there would be no solution.

Robots have a hard-enough time doing their jobs at all. Burdening them with unnecessary features and expectations worsens the problem. That’s one reason I’m always vexed when designers festoon their robots with anthropomorphic features—they make a promise no robot can keep. Anthropomorphic features and behaviors hint that the robot has the same sort of inner life as people. But it doesn’t. Instead the robot has a limited bag of human-mimicking tricks. Once the owner has seen all the tricks, the robot’s novelty is exhausted and along with it the reason for switching on the robot. Only robots that perform useful tasks remain in service after the novelty wears off.

No commercially successful robot I’m aware of has superfluous extras. This includes computation cycles—cycles it might use to contemplate world domination. All of the robot’s resources are devoted to accomplishing the task for which it was designed, or else it wouldn’t be successful. Working robots don’t have time to take over the world.

Robots have been slow to appear because each one requires a rare confluence of market, task, technology, and innovation. (And luck. I only described some of the things that nearly killed Roomba.) But as technology advances and costs decline, the toolbox for robot designers constantly expands. Thus, more types of robots will cross the threshold of economic viability. Still, we can expect one constant. Each new, successful robot will represent a minimum—the simplest, lowest-cost solution to a problem people want solved. The growing set of tools that let us attack ever more interesting problems make this an exciting time to practice robotics.

Joe Jones is cofounder and CTO of Franklin Robotics. A graduate of MIT, he holds more than 70 patents.

Lead image: Christa Mrgan / Flickr