A truck is traveling on the freeway. Inside, stacks of bananas are piled high. Picked a few weeks ago at a plantation, they’ve traveled overseas in climate-controlled cargo ships, their color still green and unappetizing. But that won’t last for long. A colorless gas with a faint, sweet, and musky odor seeps from an open pouch placed inside the truck, quietly transforming the fruit en route. By the time the tropical fruit is in your grocery basket, they are a golden yellow.

This is not science fiction, but yet another attempt at perfecting the tropical fruit delivery process—a new ripening-on-the-go trick that Professor Bhesh Bhandari and his Ph.D. student Binh Ho at the University of Queensland, Australia, are now experimenting with. For the past two centuries, bananas have traveled the world by all modes of transportation. In the late 1800s, it was by railroads—tracks were built solely for banana transport. In the 1900s, bananas were trekked in refrigerated ships—gleaming white fleets with radio technology that allowed vessels to coordinate their arrival times with harvesting schedules. In his book, Banana: The Fate of the Fruit that Changed the World, Dan Koeppel says that the banana industry “invented fast food in a way.” A banana may be healthier than a burger, but how it’s brought to you is not all that different. Before the fast-food industry learned to process, pack, and ship inexpensive temperature-controlled meals, banana carriers had already perfected their own shipping process. “If you look at the model of the industrialized supply chain, what they really came up with was a lot closer to what a fast-food chain does,” he says. The result “is bananas that arrive at the market on their final green day, and which will last exactly seven days before turning brown.”

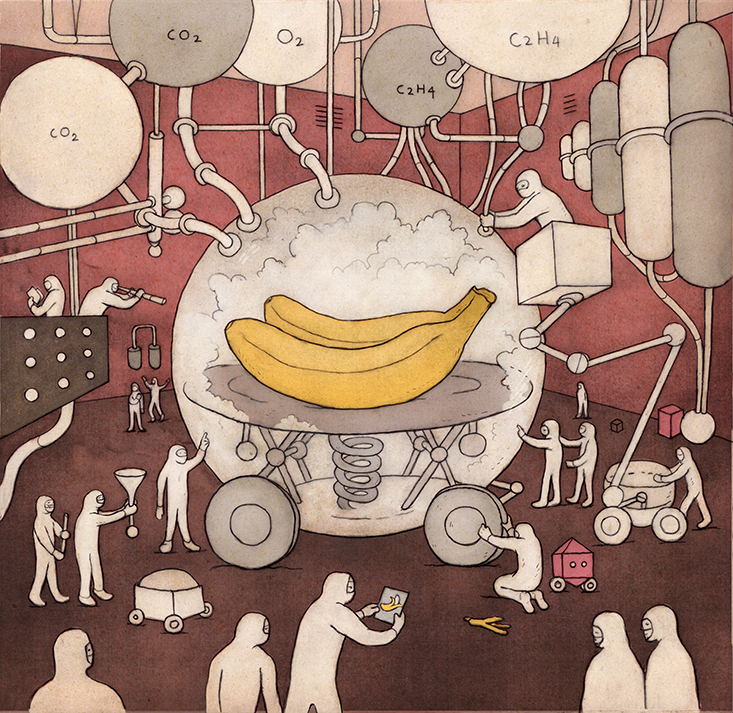

By the time bananas land on the supermarket shelf, their ripening process has already been carefully engineered through the use of three gases: ethylene, carbon dioxide, and oxygen. “To bring this tropical fruit to distant markets and have it be edible is kind of amazing,” says Randy Ploetz, a professor of plant pathology at the University of Florida. “It’s pretty much a science.”

It is indeed. The banana is “a climacteric fruit, which means that once the ripening process begins, you can’t stop it,” explains Ploetz. “So the idea is to harvest the fruits when they are mature but not ripening.” When banana bunches are cut off at harvest, they start to release ethylene, triggering a decrease of pectin and a breakdown of starch, which softens and sweetens the fruit. As part of that “senescence process,” Ploetz adds, bananas also release carbon dioxide. But high levels of carbon dioxide and ethylene would cause bananas to ripen too fast or to spoil before they arrive to consumers. Like many other climacteric fruits, bananas are sensitive to carbon dioxide— if carbon dioxide levels rise to more than 7 percent, the fruit will soften while still green and won’t taste good. So the transportation companies use a full-blown climate-control system for their capricious passengers. When bananas are loaded onto a ship, they are cooled off to 54 to 58 degrees Fahrenheit, depending on the length of the future voyage, and the levels of oxygen and carbon dioxide are maintained at 5 percent each, according to Carrier Transicold, a company that designs trucks and ships to transport bananas worldwide. Plus, humidity levels are kept between 90 and 95 percent, to keep the fruit moist.

A banana may be healthier than a burger, but how it’s brought to you is not all that different.

Before bananas board refrigerated ships bound for foreign ports, plantation workers place a tracking device that looks like a complex calculator into each crate to record the climate-control data vital for the fruits’ health. The device stays with the dainty travelers throughout the entire journey until they arrive at a store. Since the 1930s, bananas always had to make a stopover between the ship and the supermarket—namely at a ripening room, a massive warehouse where they are not only allowed to finally turn yellow, but are gassed with ethylene to quicken the process. Such rooms are expensive to maintain, and Bhandari and Ho are experimenting with ripening fruits en route. But gassing fruits inside moving trucks is problematic—ethylene is combustible and can’t safely be used in large volumes. So the scientists developed a way to store ethylene in a powder form.

The new invention encapsulates ethylene into modified cyclodextrin, a compound made up of sugar molecules bound together in a ring—essentially a form of starch. Cyclodextrin has cavities in its crystalline structure which can entrap the ethylene molecules. Cameron Turner, whose role at the university is to commercialize new technologies, likens the structure to an egg carton—a degradable shell that hosts molecules rather than eggs. When a bag or box of the powder is opened in a truck full of produce, the cyclodextrin’s crystalline structure breaks down because of the humidity in the air—and begins to slowly release ethylene over time.

The effort exerted in planning and transporting bananas can seem, well, bananas. But be honest—you wouldn’t give green or brown-spotted versions a second glance. You want the perfectly ripe stuff, and this is what Bhandar and Ho christened their invention. They plan to begin testing RipeStuff in a trial fleet of trucks with interested customers in 2014. For the time being, most bananas still have to make their final stopovers in ripening rooms. However, when RipeStuff is ready to be used commercially—the researchers estimate by 2015—this already fast fruit will arrive at your store even faster. Ploetz calls banana transport a science as it is. But with the decomposing cyclodextrin and the timed release of ethylene, your banana delivery will become even more of a science project than ever before.

Gloria Dawson is a journalist based in New York City, where she writes about science, food, and a smattering of other topics. Her writing has appeared in The Wall Street Journal, National Geographic online, Modern Farmer, and Quartz, among other publications.