A common enemy befouls surgeons, plumbers, and sailors alike: slime. In each of their professions, they wage ceaseless war against biofouling—layers of living organisms that stick around exactly where we don’t want them. Removing these various scum layers is a billion-dollar endeavor.

Boats were among the first documented victims of biofouling. Most notably, barnacles are infamous for causing turbulence; their buildup makes ships less streamlined, resulting in slower deliveries and up to 50% more fuel consumption. Over time, barnacles will also damage the hull of a ship if they’re not removed—a task made challenging by the fact that they produce one of the strongest known natural adhesives. In 1987 barnacles were estimated to cost the world economy about $170 billion per year.

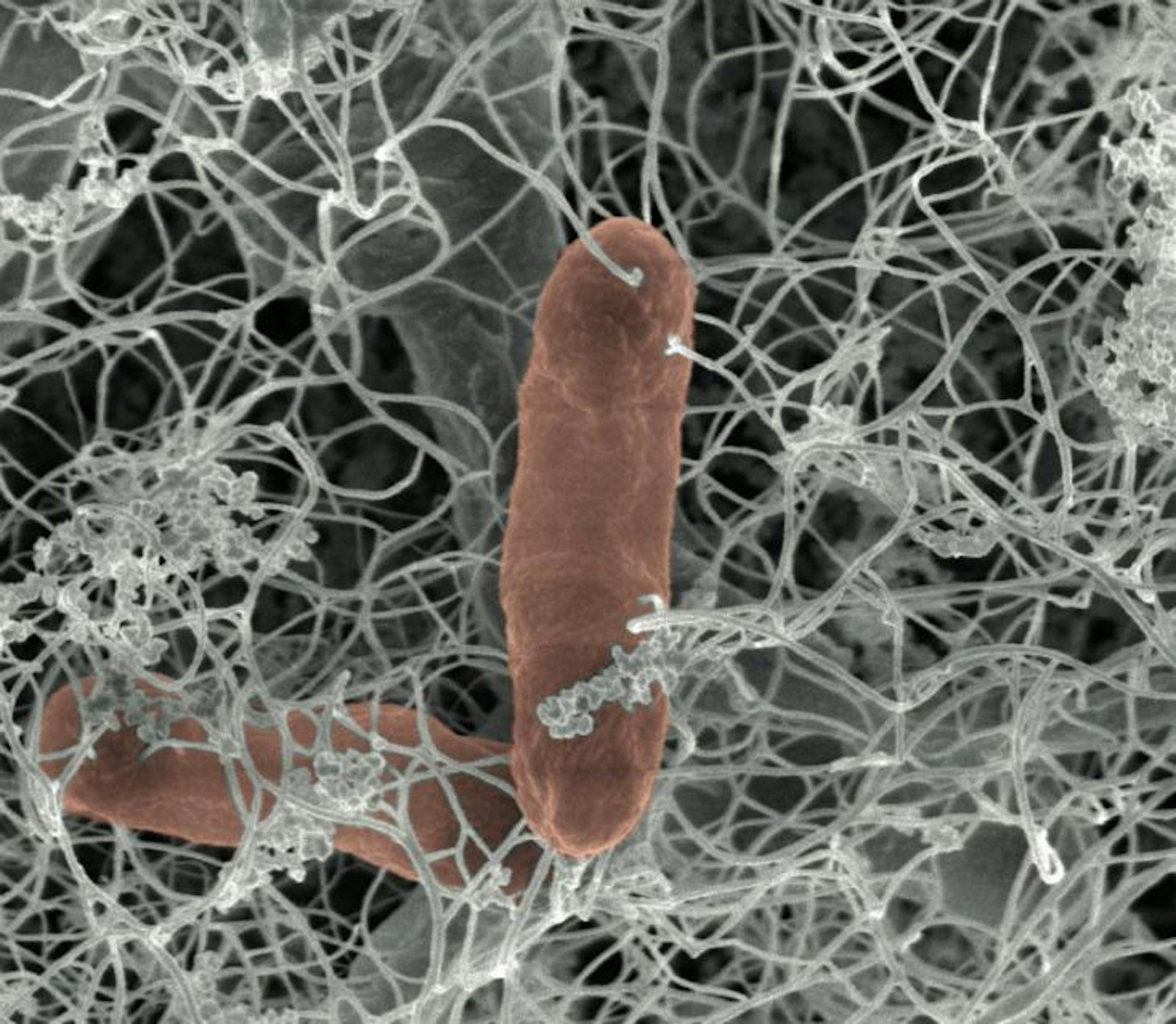

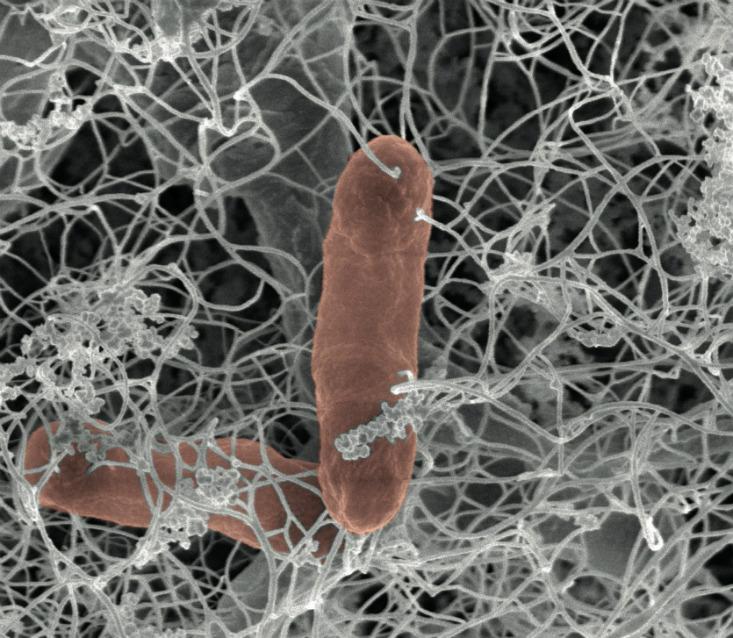

At a smaller scale, bacteria also form problematic gunk. Bacterial films in the biomedical industry have proven enormously problematic. Eighty percent of all bacterial infections are caused by bacteria arranged in biofilms, the microbes’ slimy coatings. The Foley catheter—a long tube inserted into the bladder through the urethra—is one of the most common medical devices in the world and the number-one source of hospital-acquired infection. When a patient requires catheterization for more than four weeks, the chances of acquiring a UTI approach 100 percent. Catheter-associated UTIs are estimated to cost the United States as much as a half a billion dollars (pdf) annually.

Communal living confers a number of advantages to bacteria. For one, the slimy coating on a biofilm’s surface can shield microbes from harmful antibiotics. Cells in a biofilm also tend to multiply less rapidly. While this initially might seem like a disadvantage, it comes in handy for dodging drugs like penicillin, which only target dividing cells. What’s more, biofilms are usually composed of a diverse assortment of microbial species all mixed together and swapping genetic material like a microscopic United Nations orgy. Small pieces of DNA called plasmids, which often contain genes for useful traits like antibiotic resistance, are exchanged more readily in biofilms simply due to the proximity of the bacteria cells. All these features combine to create microbial communities that can be a hundred or a thousand times more resistant to antibiotics than their free-floating counterparts.

People have been fighting biofouling, often with checkered success, for thousands of years. Ancient civilizations coated ships with oils, tars, and toxic chemicals in order to keep the hulls sleek and streamlined. Until recently, strategies for keeping barnacles at bay relied on the use of toxic paints made with harmful metals like tin and copper. These “bottom paints” were effective anti-fouling agents but at the cost of serious environmental damage. In particular, tributyltin (TBT), a tin-based molecule, caused catastrophic damage to marine ecosystems the world over.

The biomedical industry seems to have fallen into the same rut. Antibiotic coatings have been built into the plastics of catheters with varying success. But antibiotics face similar issues to TBT: They also kill normal urinary-tract bacteria, which, as in the digestive tract, might make it easier for bad bacteria to take hold once antibiotics are cut off (pdf). Microbe-killing catheters are also expensive, and—as we’ve seen with other blanket uses of antibiotics—bacteria will eventually develop resistance to them.

Biofilms are usually composed of a diverse assortment of microbial species all mixed together and swapping genetic material like a microscopic United Nations orgy.

When TBT-containing paint was banned in 2001, marine anti-fouling strategies were forced to adapt. One of the most promising tools came about after materials scientist Anthony Brennan noticed one class of sea animals that stayed remarkably free of biofouling: sharks.

The secret of the shark’s anti-fouling aptitude is a product of a clever adaptation in its scales, or denticles. Under a microscope, shark denticles look like diamond-shaped shingles layered on a roof. Their ridges create a surface with what scientists call “low wettability.” Similar to Teflon, water droplets bead up and slide off of denticles, which decreases drag in turbulent water. The constant, unimpeded flow of water over the shark’s body also makes it hard for barnacles to get established. Additionally, the tiny ridges keep would-be hitchhikers from getting comfortable—like trying to sleep on a foldout couch with the support bar smashed into your lower back.

While Brennan and his team were designing plastic films that mimicked the surface structures of shark denticles, they realized that their prototypes were particularly successful in warding off tubeworms, a common biofouler. Brennan hypothesized that the tubeworms were struggling because the synthetic shark skin was actually keeping away bacteria, which tubeworms need to bond to a surface. Subsequent tests showed he was right. Brennan’s discovery would lead to the formation of Sharklet—a company that now sells strips of antimicrobial plastic films for use on everything from bathroom stall doors to medical product packaging.

It seems that the catheter market is ripe for a sharkskin nano-coating, and indeed, Sharklet is currently developing just such a product. But researchers at Duke University may have hit on an even more effective, lower-tech solution. “It’s one of those great ideas that looks really obvious in retrospect,” says Vrad Levering, a postdoctoral candidate and the primary inventor of the innovative new catheter design. Cheaply producible using 3D printing, Levering’s design features an additional, secondary channel running alongside the standard catheter tube. The second channel can be inflated with air or water, causing the walls of the primary tube to compress or stretch. The deformation is sufficient to dislodge a developing biofilm from the walls of the tube; the bacteria then get harmlessly flushed away in the urine. “We wanted to go for worst case. We had [the biofilm] thick and funky on there,” says Levering. The double-barreled device is still a prototype, but so far, it looks promising.

By using more focused, physical attacks rather than the indiscriminate chemical weapons of yesteryear, we might finally take command in the war against biological scum. If the trend continues, arteries, plumbing, and boats all stand to gain. Our blood, wastewater, and ocean liners could slide into the future along new paths of lower resistance.

David Shultz is a Nautilus editorial intern.